The Ultimate Guide to Choosing the Best High Pressure Hose for Your Needs

When it comes to selecting the right equipment for demanding tasks, a high pressure hose plays a crucial role in ensuring efficiency and safety. Whether you're working in industrial settings, performing automotive repairs, or managing agricultural operations, the quality and specification of your high pressure hose can significantly impact your performance. This guide aims to provide you with essential insights into the various factors you should consider when choosing a high pressure hose tailored to your specific needs.

Understanding the characteristics and applications of high pressure hoses is vital. Factors such as material, diameter, pressure rating, and temperature resistance must be taken into account to ensure optimal functionality and longevity. Additionally, you will learn about the different types of high pressure hoses available and how each one suits different applications. By the end of this guide, you will be equipped with the knowledge necessary to make an informed decision, enabling you to select the best high pressure hose that meets your requirements while ensuring safe and effective operation.

Understanding High Pressure Hoses: Types and Applications

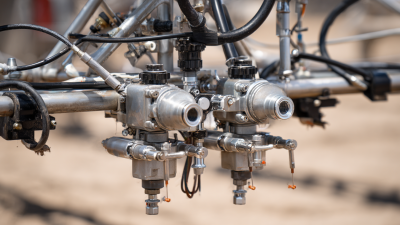

High pressure hoses are essential components in a variety of applications, ranging from industrial machinery to automotive systems. These hoses are specifically designed to withstand high pressure and transport fluids effectively, making them vital in processes where reliability and performance are crucial. There are several types of high pressure hoses, each suited for different tasks. Common types include rubber, PVC, and stainless steel braided hoses, each offering unique properties, such as flexibility, durability, and resistance to chemicals or extreme temperatures.

Understanding the applications for high pressure hoses is equally important in selecting the right one for your needs. In construction and manufacturing settings, high pressure hoses are often used for hydraulic systems, powering equipment like lifts and presses. In automotive services, they provide essential connections for power steering and braking systems. Additionally, high pressure hoses are commonly employed in pressure washing and cleaning applications, being able to effectively remove dirt and grime from surfaces. Choosing the appropriate type of hose ensures optimal functionality and safety, preventing potential malfunctions or accidents in demanding operational environments.

The Ultimate Guide to Choosing the Best High Pressure Hose

This chart represents the common applications of high pressure hoses along with their respective pressure ratings in psi (pounds per square inch). Understanding these applications can help you make an informed decision in selecting the right high pressure hose for your specific needs.

Key Factors to Consider When Selecting a High Pressure Hose

When selecting a high pressure hose, several key factors must be considered to ensure optimal performance and safety. One of the most critical aspects is the hose material, which typically ranges from rubber to thermoplastic. Rubber hoses are known for their flexibility and resistance to weathering, making them ideal for outdoor applications, while thermoplastic options exhibit excellent chemical resistance. According to the Hydraulic Institute, the choice of material can significantly affect the lifespan of the hose, with rubber hoses often lasting up to 10% longer than their thermoplastic counterparts in similar conditions.

Another important consideration is the pressure rating of the hose. High pressure hoses are categorized by their maximum working pressures, which can vary significantly based on application requirements. Industry standards indicate that a hose should be rated for at least 25% more than the maximum pressure it will encounter during use. This safety margin is crucial to prevent blowouts and maintain operational integrity. A report by the Fluid Power Journal highlights that approximately 30% of hose failures are due to inadequate pressure ratings, underscoring the importance of this factor in selection.

Finally, the diameter of the hose plays a vital role in both flow rate and pressure loss. Hoses with larger diameters can transmit more fluid but may also lead to increased weight and bulkiness, which can be challenging in certain applications. A study by the American Society for Testing and Materials (ASTM) indicates that a 50% increase in diameter can yield a 100% increase in flow capacity, but careful consideration must be given to application scenarios to balance efficiency and practicality.

Material Options: Rubber, PVC, and Stainless Steel Explained

When selecting a high pressure hose, the material from which it is made plays a crucial role in determining its performance and suitability for your specific needs.

Rubber hoses are widely recognized for their flexibility and resilience. They can endure extreme temperatures and offer excellent abrasion resistance, making them a popular choice for various applications, including agricultural, industrial, and automotive uses. However, rubber hoses may be less effective in environments where exposure to oils and chemicals is a concern, requiring careful consideration of their chemical compatibility.

On the other hand, PVC hoses provide an economical alternative with decent performance for light to moderate applications. They are lightweight, resistant to corrosion, and have a degree of flexibility. PVC hoses are ideal for situations where high pressure is required but must be monitored for temperature limitations since they may not perform as well under extreme heat.

Finally, stainless steel high pressure hoses are the most robust option, suited for severe conditions where durability and chemical resistance are paramount. These hoses can withstand high temperatures and pressures, making them suitable for heavy-duty industrial applications. Understanding the strengths and weaknesses of each material will empower you to select the right high pressure hose tailored to your requirements.

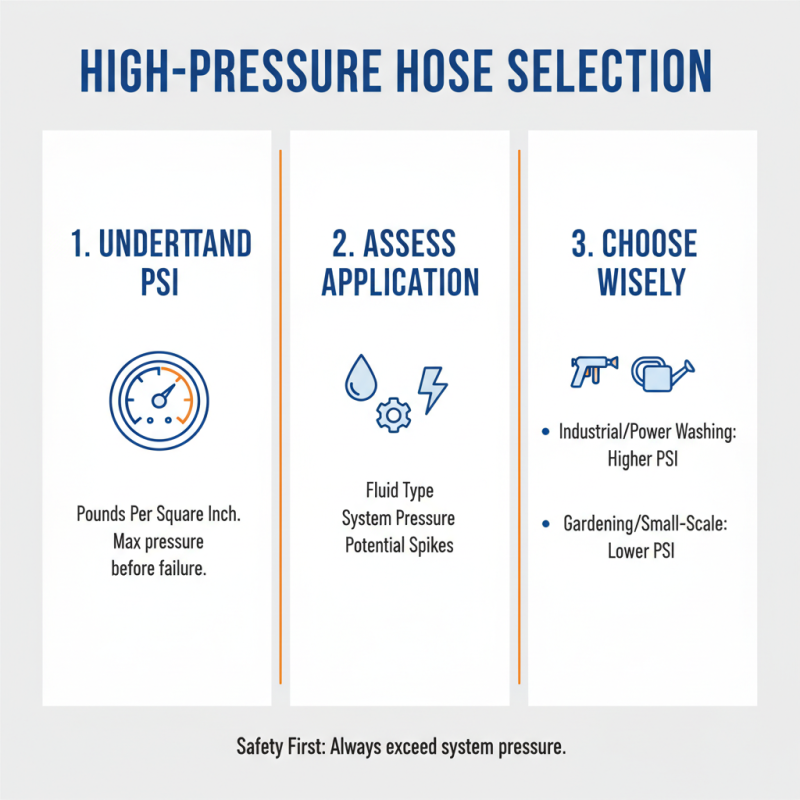

Pressure Ratings: How to Determine the Right PSI for Your Needs

When selecting a high-pressure hose, understanding pressure ratings is crucial. PSI, or pounds per square inch, reflects the pressure a hose can withstand without failing. To determine the right PSI for your needs, start by assessing the specific requirements of your application. Consider the type of fluid being transferred, the system's pressure, and any potential for pressure spikes. For instance, industrial cleaning or power washing typically demands hoses that can handle higher PSI, while gardening or small-scale applications may require less.

Next, it’s essential to factor in safety margins. Choose a hose with a pressure rating significantly higher than your maximum operating pressure. This approach not only ensures reliability but also extends the lifespan of the hose. Additionally, evaluate environmental factors such as temperature extremes and exposure to chemicals, as these can influence the hose’s performance. By carefully assessing these elements and selecting a hose with an appropriate PSI rating, you can ensure optimal performance for your specific applications while enhancing safety and durability.

Maintenance Tips for Prolonging the Life of Your High Pressure Hose

High pressure hoses are essential tools for a variety of industries, from cleaning services to construction. Proper maintenance is crucial to ensure longevity and optimal performance. A study by the Hose Manufacturer's Association (HMA) revealed that regular upkeep of hoses can extend their life by up to 50%. This not only saves costs but also enhances safety during operation.

To effectively maintain your high pressure hose, it’s essential to inspect it regularly. Look for signs of wear, such as cracks or bulges, which can compromise the hose's integrity. Additionally, proper storage significantly influences durability. Always store hoses in a cool, dry place away from direct sunlight. This can prevent the degradation of materials, which can occur due to UV exposure.

Another vital tip is to flush the hose after use. Residual chemicals or materials can damage the inner lining over time. According to industry data, failing to clean hoses properly can lead to a 30% decrease in performance efficiency. By implementing these maintenance strategies, you can enhance the lifespan of your high pressure hose and ensure it continues to operate safely and effectively for years to come.

Related Posts

-

How to Choose the Right Sprayer Parts for Optimal Performance

-

How to Choose the Right Stainless Steel Ball Valve for Your Project

-

How to Choose the Right High Pressure Hose for Your Specific Applications

-

Essential Checklist for Choosing the Right Sprayer Parts to Maximize Efficiency and Performance

-

Top 7 Benefits of Using a Stainless Steel Hose Reel for Your Garden

-

5 Best Strategies for Choosing the Right Hose Reel for Your Needs