Top Tips for Choosing the Right Pressure Hose for Your Cleaning Projects

Choosing the right pressure hose is crucial for maximizing the efficiency of your cleaning projects. According to a recent industry report by the International Cleaning Association, selecting an appropriate pressure hose can enhance cleaning performance by up to 30%. The report underscores the importance of hose durability, flexibility, and pressure ratings in achieving optimal results in various applications. As noted by industry expert Dr. Harold Jennings, renowned for his research on cleaning technologies, "The correct pressure hose can significantly impact both productivity and safety in cleaning operations."

In today’s competitive marketplace, professionals and DIY enthusiasts alike are inundated with choices when it comes to pressure hoses. A well-informed decision not only ensures effective cleaning but also prolongs the lifespan of both the hose and the cleaning equipment. With advancements in material technology, such as reinforced thermoplastics and rubber compounds, the options available can meet the diverse demands of various cleaning tasks. As you embark on your selection process, keep in mind that understanding the specific requirements of your projects will lead to better outcomes and a return on your investment.

Understanding the Different Types of Pressure Hoses for Cleaning

When embarking on a cleaning project, selecting the right pressure hose is crucial to ensure efficiency and effectiveness. Understanding the different types of pressure hoses is essential for making an informed decision. There are primarily three types of pressure hoses used in cleaning: PVC, rubber, and reinforced. PVC hoses are lightweight and affordable, making them ideal for light-duty tasks. They typically handle pressures up to 2,500 PSI, according to industry standards. On the other hand, rubber hoses are more durable and can withstand higher pressures, often up to 4,000 PSI, making them suitable for heavy-duty applications.

Reinforced hoses, which often feature additional layers of woven fabric, provide extra strength and flexibility. They are known for their longevity and resistance to abrasions, handling pressures up to 5,000 PSI. Reports from the National Cleaning Contractors Association indicate that using the right type of pressure hose correlates with a 30% increase in cleaning efficiency and a significant reduction in maintenance costs over time. Moreover, various projects may require hoses with specific features, such as resistance to chemicals or temperature extremes, which further emphasizes the importance of understanding the unique characteristics of each hose type. Selecting the appropriate pressure hose tailored to your specific cleaning needs will ultimately lead to more successful outcomes.

Evaluating Pressure Hose Material for Durability and Flexibility

When selecting a pressure hose for cleaning projects, evaluating the material is crucial for ensuring both durability and flexibility. Industry standards emphasize the importance of material characteristics in determining the performance and longevity of pressure hoses. According to a report from the Pressure Washing Manufacturers' Association (PWMA), hoses made from high-quality rubber exhibit superior flexibility and resistance to wear, primarily due to their enhanced tensile strength and elasticity. This flexibility not only improves maneuverability during cleaning tasks but also decreases the likelihood of kinks or punctures, which can compromise performance.

Furthermore, thermoplastic materials have gained popularity due to their lighter weight and excellent resistance to chemicals and weather conditions. A recent study found that pressure hoses constructed from thermoplastic elastomers (TPE) can resist degradation from various cleaning agents, extending the lifespan of the hose up to 30% compared to traditional rubber hoses. This can be particularly advantageous for commercial operations where hoses are subjected to intensive use and exposure to harsh environments. By choosing the right material, users can ensure that they invest in a pressure hose that will withstand the rigors of their cleaning projects while maintaining efficiency and performance.

Choosing the Right Size of Pressure Hose for Your Equipment

When selecting a pressure hose for your cleaning projects, determining the right size is crucial for achieving optimal performance. Firstly, you should consider the specifications of your cleaning equipment. Each pressure washer is designed to work with hoses of specific diameters and lengths; using a hose that is too long or too narrow can hinder water flow and reduce the effectiveness of your cleaning tasks. The diameter of the hose directly affects the pressure and flow rate. A wider hose allows for more water to flow through, making it suitable for larger tasks, while a narrower hose can suffice for smaller, precision jobs.

Additionally, think about the reach you need for your cleaning projects. A longer hose provides more flexibility and access to hard-to-reach areas, but it can also reduce pressure if it exceeds the recommended length for your equipment. It’s essential to strike a balance between length and pressure retention; typically, hoses up to 100 feet are adequate for most residential applications without significantly compromising performance. Always refer to your equipment manual to ascertain the manufacturer’s recommendations regarding hose size, ensuring that your cleaning efforts are both effective and efficient.

Top Tips for Choosing the Right Pressure Hose for Your Cleaning Projects

| Hose Length (ft) | Diameter (in) | Max PSI | Material | Recommended Use |

|---|---|---|---|---|

| 25 | 1/4 | 2700 | PVC | Residential Cleaning |

| 50 | 3/8 | 4000 | Rubber | Commercial Cleaning |

| 100 | 3/8 | 3000 | Polyurethane | Industrial Applications |

| 75 | 1/4 | 3500 | Reinforced Rubber | Heavy Duty Cleaning |

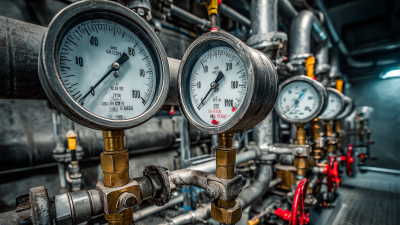

Assessing Pressure and Temperature Ratings for Effective Cleaning

When selecting the right pressure hose for your cleaning projects, understanding the pressure and temperature ratings is crucial for ensuring effective performance. The pressure rating of a hose indicates the maximum pressure the hose can handle without failing, which directly affects its ability to clean various surfaces. For instance, surfaces that are heavily soiled or have tough stains may require a hose that can handle higher pressure levels. It's essential to match the hose's pressure rating with the requirements of your cleaning job, taking into account the amount of pressure needed to effectively remove dirt and grime without damaging the surface.

In addition to pressure ratings, the temperature rating of the hose is equally important. Different cleaning tasks may require hot water to achieve optimal cleaning results, especially for grease and oil stains. A hose with a higher temperature rating will ensure that it can handle hot water without degrading or losing its structural integrity. When assessing your options, consider the environments in which you will be using the hose and select one that meets both the temperature and pressure requirements of your specific cleaning applications. Making informed decisions based on these factors will lead to more efficient and effective cleaning outcomes.

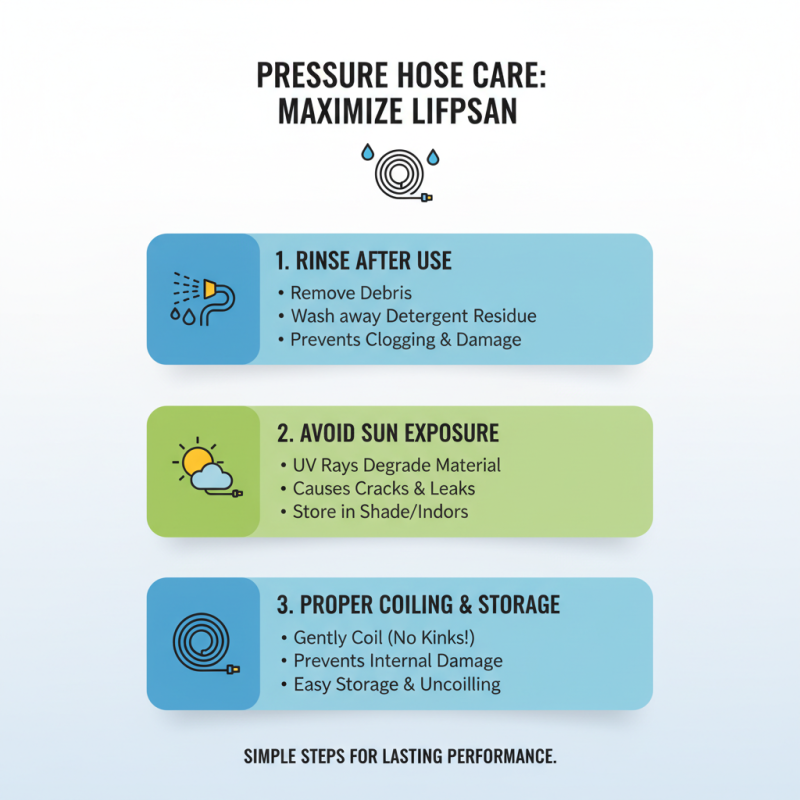

Tips for Maintaining and Storing Your Pressure Hose Properly

When it comes to maintaining and storing your pressure hose, a few simple practices can significantly enhance its longevity and performance. After each use, it's essential to thoroughly rinse out the hose with clean water to remove any debris or detergent residues that could cause damage over time. Avoid leaving the hose under direct sunlight for extended periods, as UV rays can degrade the materials. Instead, gently coil the hose without kinks or sharp bends, preventing any internal damage and making it easier to store when not in use.

Proper storage is equally crucial for maintaining your pressure hose. Ideally, you should store the hose in a cool, dry location, away from extreme temperatures and moisture that could lead to mold or mildew growth. Using a dedicated storage reel can help keep the hose organized and minimize wear and tear caused by tangling. Also, regularly inspect your hose for any signs of wear, such as cracks or frays. Catching these issues early will allow for repairs or replacements before they worsen, ensuring your pressure hose remains reliable for all your cleaning needs.

Related Posts

-

7 Proven Tips for Finding the Best High Pressure Hose for Your Needs

-

Unlocking Efficiency: How to Choose the Right Pressure Washer Hose for Every Job

-

7 Essential Tips to Maximize Efficiency with Electric Hose Reels: Boost Your Productivity by 30%

-

Unlocking the Power of Pressure Washer Pumps for Optimal Cleaning Efficiency and Performance Insights

-

How to Choose the Right Pressure Gauges for Your Industrial Needs

-

Exploring Innovative Sprayer Parts at the 138th Canton Fair 2025 Insights and Industry Trends