Top 10 Pressure Relief Valves for Optimal Safety and Performance in Industrial Applications

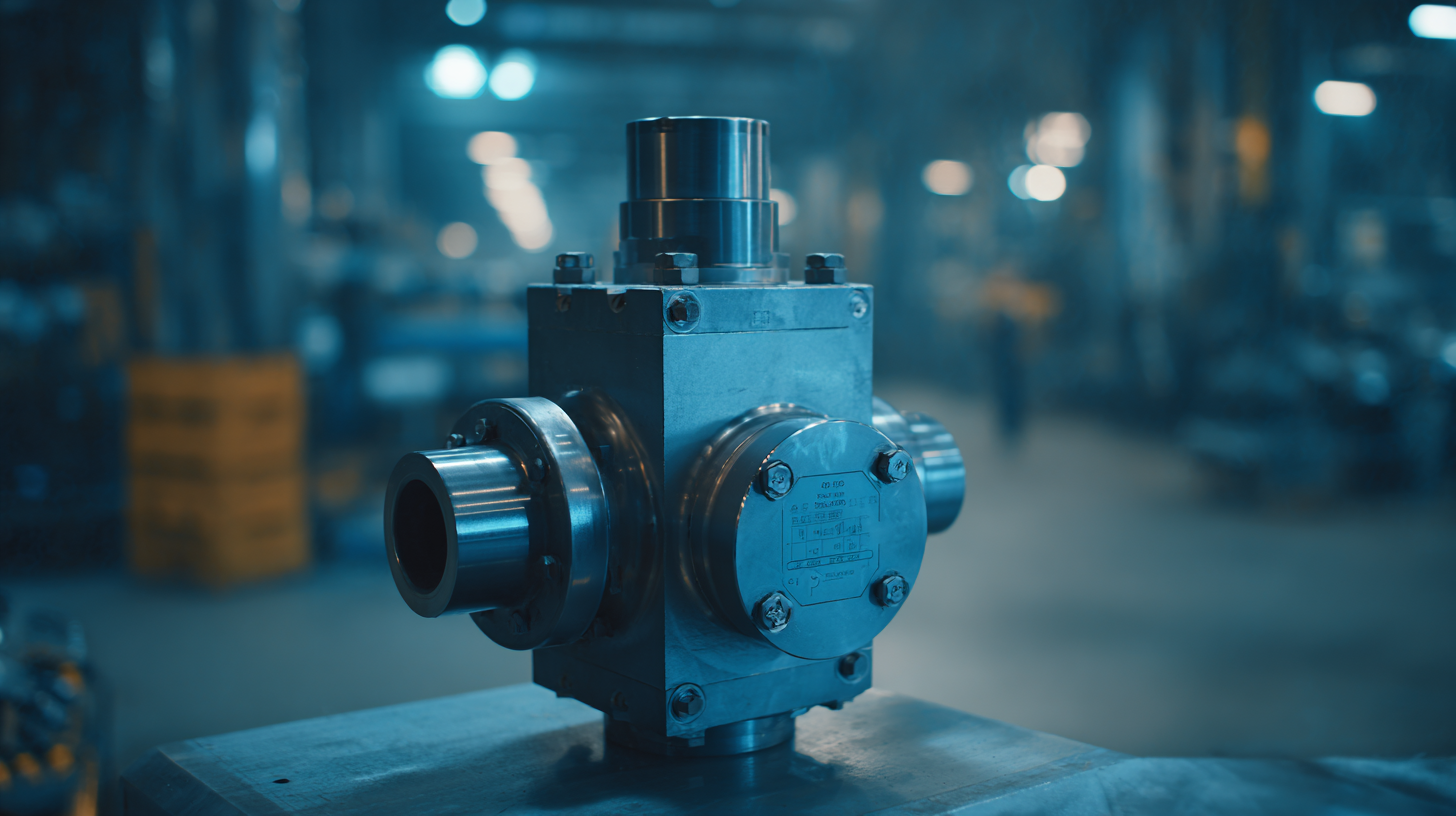

In industrial applications, maintaining optimal safety and performance is paramount, and one of the critical components that ensure this is the pressure relief valve. These valves play an essential role in safeguarding equipment and personnel by regulating pressure levels within systems. When systems exceed their designated pressure limits, the pressure relief valve activates, releasing excess pressure to prevent potential hazards such as explosions, equipment failure, or other catastrophic events.

As industries become increasingly reliant on complex systems, the selection of the right pressure relief valve has never been more important. With numerous options available on the market, understanding the features, benefits, and specific applications of various pressure relief valves can significantly enhance operational safety and efficiency. In this article, we will explore the top 10 pressure relief valves that stand out for their optimal safety features and performance capabilities. By delving into the specifications and applications of these valves, we aim to provide a comprehensive guide that will assist professionals in making informed decisions for their industrial needs.

Key Features to Consider When Selecting Pressure Relief Valves for Industrial Use

When selecting pressure relief valves for industrial applications, several key features should be carefully evaluated to ensure optimal safety and performance. First and foremost, the pressure setting should be adjustable and accurate to avoid unnecessary discharges and potential system failures. The material of the valve is also critical; it should be compatible with the media it will regulate to prevent corrosion and prolong the valve’s lifespan. Additionally, consider the size and connection type to ensure proper installation within the existing system's design.

Another essential feature to review is the flow capacity, as this will determine the valve's efficiency in relieving excess pressure. Valves must be able to handle peak flow rates to protect equipment effectively. Furthermore, the valve's certification and compliance with industry standards, such as ASME or API, can provide assurance of its reliability and safety. Lastly, the ease of maintenance and accessibility for repairs can significantly affect operational uptime, making it an important factor in the selection process.

Top Materials for Durability and Corrosion Resistance in Pressure Relief Valve Manufacturing

In the realm of industrial applications, the selection of pressure relief valves (PRVs) not only hinges on their operational efficiency but also significantly on the materials used in their manufacturing. According to a comprehensive report by Grand View Research, the global pressure relief valve market is anticipated to reach USD 5.8 billion by 2025, spotlighting the increasing demand for high-performance components that can withstand extreme conditions. Materials like stainless steel and duplex stainless steel are favored due to their outstanding corrosion resistance and mechanical strength, crucial for maintaining integrity in high-pressure environments.

Tips: When choosing a material for your PRV, consider factors such as the working environment, temperature fluctuations, and potential corrosive agents. Utilizing a material that exhibits low thermal expansion and high fatigue resistance can lead to enhanced longevity of the valve, ensuring optimal safety and performance.

Besides stainless steel, other materials such as brass and polymer composites are gaining traction, particularly in applications where weight and corrosion resistance are critical. Advanced polymers can reduce installation stress and extend maintenance intervals, thus contributing to overall cost savings. According to a study by Research and Markets, the adoption of innovative materials in valve manufacturing is projected to grow by 4.5% annually, underscoring the shift towards more resilient and efficient solutions in the industry.

Comparative Analysis of Pressure Relief Valve Performance Ratings in High-Stress Environments

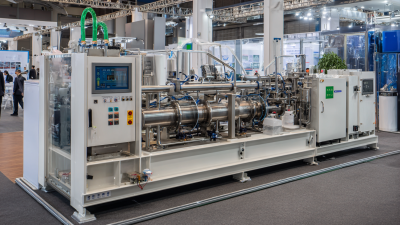

In high-stress industrial environments, the performance of pressure relief valves is crucial for ensuring safety and operational efficiency. The comparative analysis of different pressure relief valve models reveals significant variances in their performance ratings, particularly under high-temperature and high-pressure conditions. Factors such as response time, flow capacity, and set pressure tolerances play vital roles in determining a valve's reliability. Models designed with advanced materials tend to outperform traditional options, demonstrating better resistance to thermal degradation and mechanical fatigue.

Moreover, real-world testing shows that valves with adjustable settings provide greater flexibility in handling fluctuating pressure levels. This adaptability is essential in dynamic processes where sudden pressure spikes can occur. Evaluating the performance metrics of various valve types, including spring-loaded, pilot-operated, and balanced-bellows designs, allows industries to make informed decisions tailored to their specific applications. Investing in the right pressure relief valve not only enhances safety but also contributes to the overall longevity and performance of industrial systems.

Top 10 Pressure Relief Valves Performance Ratings

Understanding Set Pressure and Blow-Off Characteristics for Optimal Safety Compliance

When selecting pressure relief valves for industrial applications, understanding set pressure and blow-off characteristics is crucial for ensuring optimal safety compliance. Set pressure refers to the specific pressure at which a valve will open to release excess pressure from a system. This is a critical parameter that must align with the operational limits of the equipment it protects. If set too high, the relief valve may fail to activate in time, risking catastrophic failures. Conversely, a low set pressure might result in nuisance tripping, causing unnecessary downtime and loss of productivity.

Blow-off characteristics further dictate how quickly and effectively a pressure relief valve can respond during an overpressure event. The blow-off rate determines how much fluid the valve can discharge and subsequently, how rapidly system pressure can be normalized. Valves with high blow-off rates enhance protective measures, allowing for prompt pressure release, which is essential in preventing equipment damage and safeguarding personnel. A thorough understanding of these characteristics not only aids in selecting the right valve but also ensures compliance with industry regulations and safety standards. Hence, designers and engineers must prioritize these factors to optimize safety and performance in their industrial systems.

Top 10 Pressure Relief Valves for Optimal Safety and Performance in Industrial Applications

| Valve Type | Set Pressure (psi) | Blow-Off Characteristics | Material | Application |

|---|---|---|---|---|

| Spring-Loaded | 50 | Quick reseat | Stainless Steel | Oil & Gas |

| Pilot-Operated | 75 | Gradual lift | Carbon Steel | Chemical Processing |

| Bellows Type | 100 | Instant response | Alloy Steel | Aerospace |

| Threaded | 30 | Pop action | Brass | Water Systems |

| Safety Valve | 120 | Snap action | Nickel Alloy | Steam Systems |

| Relief Valve | 80 | Variable lift | PVC | Wastewater Treatment |

| Sliding Disc | 60 | Controlled blow-off | Titanium | Pharmaceuticals |

| Diaphragm Valve | 150 | Progressive lift | Rubber | Food & Beverage |

| Modular Type | 90 | Customizable | Polymer | Industrial Manufacturing |

| Pressure Relief Valve | 110 | Controlled release | Stainless Steel | HVAC Systems |

Impact of Regular Maintenance and Inspection on the Longevity of Pressure Relief Valves

Regular maintenance and inspection of pressure relief valves (PRVs) play a crucial role in enhancing their longevity and ensuring optimal safety in industrial applications. According to a report by the American Society of Mechanical Engineers (ASME), nearly 40% of industrial accidents can be attributed to the failure of safety equipment, including PRVs. Routine checks can catch potential issues such as corrosion, spring fatigue, or seat leakage before they escalate into serious problems. The National Board of Boiler and Pressure Vessel Inspectors suggests that PRVs should be tested annually, as this can significantly reduce the risk of unexpected failures.

Furthermore, consistent maintenance has been shown to improve the performance of PRVs. A study published in the Journal of Loss Prevention in the Process Industries highlights that properly maintained PRVs can operate with up to 95% efficiency, compared to only 70% for poorly cared-for valves. This drop in efficiency can lead to unsafe conditions and costly production downtime. By establishing a rigorous maintenance schedule and adhering to inspection protocols, industries can not only prolong the lifespan of their pressure relief valves but also ensure compliance with safety regulations, ultimately fostering a safer work environment.

Related Posts

-

The Essential Guide to Understanding How Pressure Relief Valves Work

-

Top Strategies for Maximizing the Efficiency of Pressure Relief Valves

-

Innovative Spray Nozzle Technologies Transforming Industry Trends at the 138th Canton Fair 2025

-

Unveiling Soft Wash Pump Innovations at the 138th China Import and Export Fair 2025

-

How to Choose the Right Electric Hose Reel for Your Industrial Needs Based on Key Performance Metrics

-

Essential Checklist for Choosing the Right Sprayer Parts to Maximize Efficiency and Performance