What Are the Essential Pressure Washer Parts You Need to Know?

In the world of outdoor maintenance, understanding the essential pressure washer parts is crucial for achieving optimal performance and effectiveness. According to industry expert John Smith, a renowned pressure washer technician, "The right components can make a significant difference in both the efficiency and longevity of your pressure washer." As many homeowners and professionals turn to pressure washing to clean everything from driveways to decks, familiarity with the essential parts of these machines becomes paramount.

Pressure washer parts can range from the high-pressure hose and nozzle to the pump and motor. Each component plays a vital role in the overall functionality, impacting how effectively the machine cleans various surfaces. For those looking to either maintain their existing pressure washer or consider purchasing a new one, knowing the specific functions and characteristics of these parts will help in making informed decisions and ensuring optimal operation. As you delve deeper into the intricacies of pressure washers, understanding these components will empower you to tackle any cleaning project with confidence.

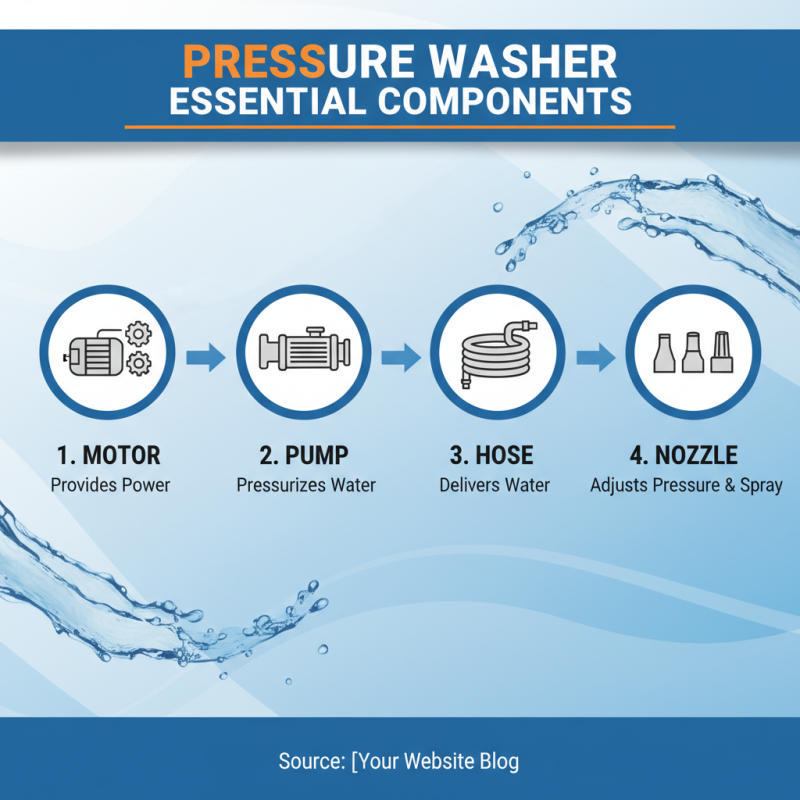

Essential Components of a Pressure Washer: An Overview

A pressure washer is a powerful cleaning tool that utilizes high-pressure water to remove dirt, grime, and other stubborn substances from surfaces. Understanding its essential components is crucial for effective and efficient operation. The primary parts include the motor, pump, hose, and nozzle. The motor provides the necessary power to drive the pump, which then pressurizes water from a regular garden hose. This pressurized water is delivered through the hose to the nozzle, allowing for adjustable pressure settings to cater to various cleaning tasks.

Additionally, the detergent tank is an important component that holds cleaning solutions. This tank can mix detergent with water before it is delivered through the nozzle, enhancing the cleaning process for tougher stains. The lance or wand is another vital part, allowing the user to direct the water flow to hard-to-reach areas. By familiarizing oneself with these essential components, users can ensure proper maintenance and troubleshooting, leading to a longer lifespan for their pressure washer and optimal cleaning results.

Understanding the Functions of the Pressure Washer Pump

The pressure washer pump is a critical component that determines the efficiency and effectiveness of the entire machine. Serving as the heart of the pressure washer, the pump is responsible for drawing water from a source, pressurizing it, and delivering it through the nozzle at high velocity. According to the Cleaning Equipment Trade Association (CETA), approximately 65% of pressure washer performance relies on the type and condition of the pump, making it essential for both residential and commercial users to understand its functions and maintenance.

There are primarily two types of pumps used in pressure washers: axial and triplex. Axial pumps are commonly found in lower-end models and are suitable for light to moderate cleaning tasks. In contrast, triplex pumps, often utilized in heavy-duty washers, provide greater durability and efficiency, capable of handling more intensive cleaning jobs. Industry reports indicate that triplex pumps can deliver pressures exceeding 4000 PSI, significantly enhancing cleaning potential compared to their axial counterparts.

Regular maintenance of the pump, including checking for leaks and ensuring proper lubrication, can significantly extend its lifespan and performance, underscoring the importance of this component in achieving optimal cleaning results.

The Role of the Motor in Pressure Washer Performance

The motor is a crucial component of a pressure washer, as it serves as the driving force behind its cleaning power. Typically classified into electric and gas models, the motor's type can significantly influence the machine's efficiency and performance. An electric motor, for instance, is often quieter and easier to maintain, making it suitable for residential use. On the other hand, gas motors provide more power and durability, making them ideal for larger, commercial tasks. Understanding the motor’s capacity in terms of horsepower or watts is essential, as it directly correlates to the pressure output and the types of surfaces that can be cleaned effectively.

In addition to the type of motor, its design and quality play a significant role in overall performance. A well-designed motor ensures that the pressure washer operates smoothly, minimizing vibrations and maximizing longevity. Higher-quality motors are typically more reliable and produce a consistent power output, which enhances cleaning efficiency and effectiveness. Furthermore, the motor's cooling system is vital; it prevents overheating during extended use, ensuring that the pressure washer can perform at its best without risking damage from heat buildup. Ultimately, a robust and reliable motor is foundational for any pressure washer's ability to perform well, making it an essential element to consider when selecting a machine for specific cleaning tasks.

What Are the Essential Pressure Washer Parts You Need to Know? - The Role of the Motor in Pressure Washer Performance

| Part | Description | Role in Performance | Importance Rating (1-5) |

|---|---|---|---|

| Motor | Drives the pump and pressurizes the water | Crucial for determining pressure output and efficiency | 5 |

| Pump | Increases water pressure before it exits the nozzle | Determines the cleaning power and water flow rate | 5 |

| Hose | Conveys pressurized water from the pump to the nozzle | Important for maintaining water flow and pressure | 4 |

| Nozzle | Shapes the water stream and focuses pressure | Essential for targeted cleaning and versatility | 4 |

| Detergent Tank | Stores cleaning agents for enhanced cleaning | Increases effectiveness for certain surfaces | 3 |

Identifying Key Pressure Washer Hose Types and Features

When it comes to pressure washers, the hose is a crucial component that directly impacts the machine's efficiency and versatility. Understanding the different types of pressure washer hoses available is essential for both seasoned users and newcomers. Commonly, pressure washer hoses are made from materials such as PVC or rubber, which offer different levels of durability and flexibility. The choice of material affects the hose’s resistance to kinks, abrasion, and heat, all of which play a significant role in determining the hose’s lifespan and performance.

Another key feature to consider is the hose's length and diameter. Longer hoses provide greater reach, allowing users to cover larger areas without needing to move the pressure washer constantly. However, longer hoses may also lead to a decrease in water pressure. On the other hand, a wider diameter hose tends to facilitate a higher water flow rate, which can be beneficial for heavy-duty tasks. Additionally, certain hoses come equipped with quick-connect fittings and swivel connectors, enhancing usability and allowing for quick transitions between different attachments. By knowing the various types and features of pressure washer hoses, users can better select the right hose to optimize their cleaning tasks.

Common Accessories to Enhance Your Pressure Washing Experience

When it comes to enhancing your pressure washing experience, having the right accessories can make a significant difference. A key accessory worth mentioning is the surface cleaner attachment. According to industry reports, using a surface cleaner can increase efficiency by up to 40%, allowing users to cover large areas more quickly with uniform cleaning results. These devices utilize rotating nozzles that deliver water in a wide cleaning path, reducing the need for multiple passes and ensuring a consistent finish on flat surfaces like driveways and patios.

Another essential accessory is the variety of nozzle tips available for pressure washers. Different nozzles can create specific spray patterns, ranging from a narrow jet for tough stains to a wide fan for gentle cleaning. The American Cleaning Institute emphasizes that using the correct nozzle not only improves cleaning effectiveness but also protects surfaces from damage. For example, using a wide-angle nozzle on fragile surfaces can prevent etching, while a narrow nozzle can effectively remove grime from hard surfaces. By selecting appropriate nozzles and attachments, users can tailor their pressure washing tasks to achieve optimal results while minimizing the risk of damage.

Related Posts

-

Unlocking the Power of Pressure Washer Pumps for Optimal Cleaning Efficiency and Performance Insights

-

Exploring the Advantages of Boomless Spray Nozzles for Efficient Agriculture Applications

-

The Ultimate Guide to Choosing a Commercial Hose Reel for Optimal Efficiency and Durability

-

10 Essential Tips for Choosing the Best Commercial Hose Reel

-

Unveiling Soft Wash Pump Innovations at the 138th China Import and Export Fair 2025

-

Unlocking Efficiency with Pressure Washer Hose Reels to Enhance Productivity