How to Choose the Best Pressure Gauges for Your Needs in 2025

In the rapidly evolving world of industrial instrumentation, selecting the right pressure gauges is crucial for ensuring safety and efficiency. As we approach 2025, advancements in technology and changing industry standards mean that professionals must be more discerning than ever in their choices. Renowned industry expert Dr. Emily Carter, a leading authority on pressure measurement solutions, emphasizes, "Choosing the right pressure gauge is not just about accuracy; it's about reliability and safety in critical applications."

With the variety of options available, from analog to digital, and various measurement ranges and materials, making an informed decision can be daunting. This guide aims to demystify the selection process for pressure gauges, highlighting essential factors to consider, including the application environment, maximum pressure limits, and the specific needs of your operations. Understanding these aspects will empower you to choose pressure gauges that not only meet technical requirements but also enhance the overall efficiency of your systems in 2025 and beyond.

Understanding Pressure Gauges: Types and Applications

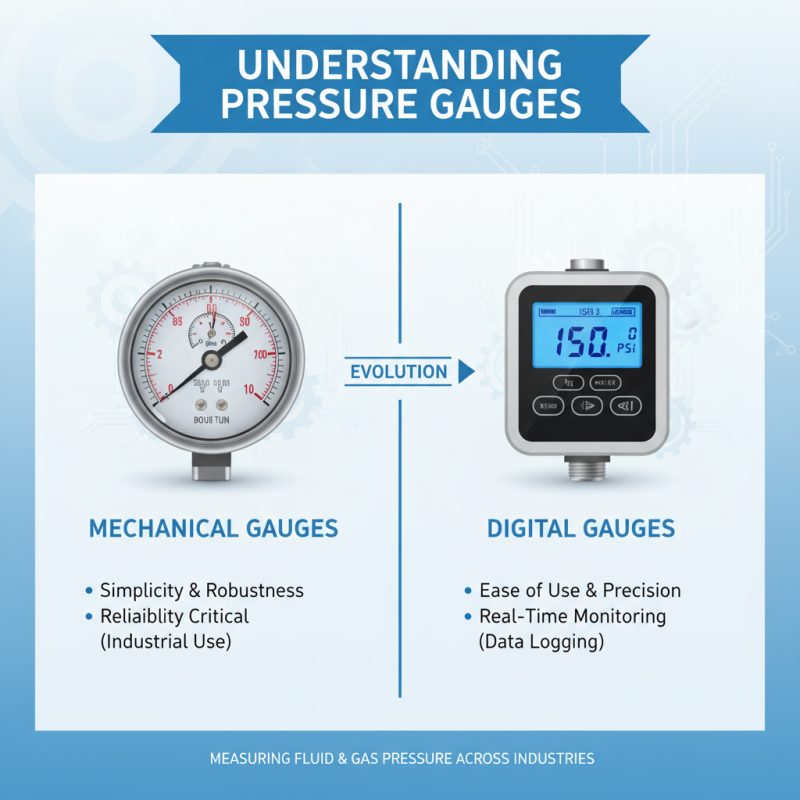

Understanding pressure gauges involves recognizing the various types available and their specific applications. Pressure gauges are essential instruments used across multiple industries to measure the pressure of fluids and gases. The most common types include mechanical gauges, such as Bourdon tube gauges, and digital gauges, which provide electronic readouts for enhanced precision. Mechanical gauges are favored for their simplicity and robustness, making them ideal for environments where reliability is critical. On the other hand, digital gauges are increasingly popular due to their ease of use and ability to display real-time data, which is particularly valuable in settings requiring accurate monitoring and data logging.

Different applications dictate the choice of pressure gauge. For instance, in the automotive industry, pressure gauges are crucial for monitoring tire pressure and ensuring optimal vehicle performance. In industrial settings, gauges are widely used to track the pressure in piping systems, tanks, and reactors, playing a vital role in safety and efficiency. Additionally, specialized gauges are designed for specific conditions, such as high-temperature or corrosive environments. Understanding the specific requirements of the application will help in selecting the most suitable pressure gauge, whether it's for routine checks in a laboratory or for rigorous use in a manufacturing facility. By appreciating the types and respective applications, users can make informed decisions to meet their operational needs effectively.

Key Factors to Consider When Choosing Pressure Gauges

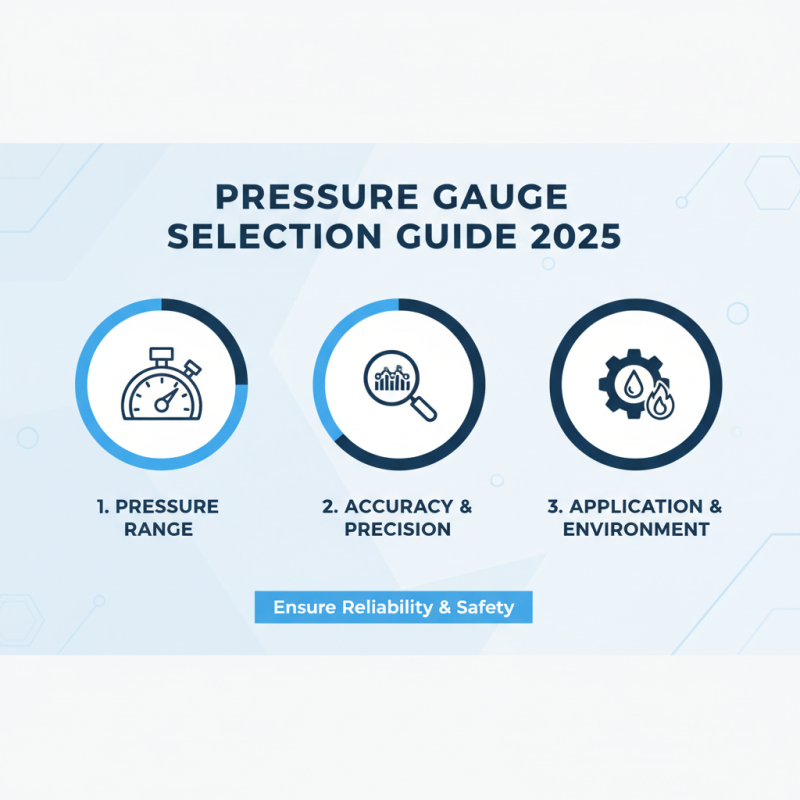

When selecting the best pressure gauges for your needs in 2025, it is essential to consider several key factors that can significantly impact performance and reliability. First and foremost, determine the pressure range required for your specific application. Different industries and tasks will have varied requirements, and choosing a gauge that accurately measures within your desired range is crucial for ensuring safety and efficiency. Additionally, consider the gauge's accuracy and precision specifications, as these will affect the reliability of your measurements when you need them most.

Another vital aspect to evaluate is the environmental conditions in which the pressure gauge will be used. Factors like temperature, humidity, and potential exposure to corrosive substances can influence the durability and longevity of the device. Look for materials and designs that can withstand your specific operating environment. Finally, consider the type of connection and installation options available. Compatibility with existing systems can save time and reduce the likelihood of installation issues, ensuring that your pressure gauge performs optimally right from the start. By focusing on these factors, you can make an informed decision that best suits your requirements.

Comparison of Analog and Digital Pressure Gauges

When it comes to selecting the right pressure gauge for your needs in 2025, understanding the difference between analog and digital gauges is crucial. Analog pressure gauges operate on a simple mechanical principle, with a needle moving across a dial to indicate the pressure. These gauges are highly durable and can function effectively in harsh environments. According to a recent industry report, analog gauges account for approximately 45% of the market due to their reliability and lower cost. They are often preferred in applications where real-time monitoring is not critical, such as in HVAC systems or water treatment facilities.

In contrast, digital pressure gauges have gained popularity due to their accuracy and ease of use. Equipped with electronic sensors and displays, they offer precise readings and can often record data over time. Market analysis indicates that digital gauges have captured around 55% of the market share, particularly in industries requiring intricate pressure management such as aerospace and pharmaceuticals. They often feature advanced functionalities like alarms and connectivity options, making them ideal for automation in modern applications.

Tip: When choosing between analog and digital gauges, consider the specific demands of your application. For high precision needs, digital gauges often provide the best performance, while analog gauges might be a better choice for simple, rugged environments. Additionally, assess the operating conditions—temperature, humidity, and vibration—as these factors can significantly impact gauge performance and longevity.

How to Choose the Best Pressure Gauges for Your Needs in 2025

| Type | Accuracy (% of Full Scale) | Range (psi) | Display | Price ($) |

|---|---|---|---|---|

| Analog Pressure Gauge | 2% | 0-100 | Needle | 25 |

| Digital Pressure Gauge | 0.5% | 0-150 | LCD | 40 |

| High-Pressure Gauge | 1% | 0-1000 | Dial | 80 |

| Digital Waterproof Gauge | 0.25% | 0-200 | LCD | 70 |

Selecting Pressure Gauges Based on Accuracy and Range

When selecting pressure gauges for your needs in 2025, accuracy and range should be your primary considerations. Accuracy refers to how close the gauge reads to the actual pressure. In applications where precision is crucial, such as in laboratory settings or critical industrial processes, high-accuracy gauges are necessary to ensure reliable data. Checking the manufacturer's specifications for accuracy, typically expressed as a percentage of full scale, can guide you in choosing the right instrument. Additionally, look for gauges that offer calibration options to maintain their accuracy over time.

The range of a pressure gauge determines the maximum and minimum pressures it can measure effectively. It's essential to choose a gauge with a range that fits your specific application. If the range is too broad, the gauge might not provide detailed readings at lower pressures, while a range that is too narrow could limit its utility. Ideally, a gauge should have a range that encompasses the operating pressures without approaching the extremes too closely. This balance ensures optimal performance, minimizes wear, and prolongs the life of the gauge. Always consider future needs as well; selecting a gauge with a slightly larger range may provide flexibility for potential changes in your application.

Future Trends in Pressure Gauge Technology for 2025

As we approach 2025, the pressure gauge industry is undergoing significant transformations influenced by technological advancements and evolving user needs. One of the most prominent trends is the integration of smart technology into pressure gauges. Modern devices equipped with IoT capabilities can not only provide real-time pressure readings but also enable remote monitoring and data logging, making them invaluable for applications in various sectors, including manufacturing and energy. According to a recent industry report, the global smart pressure gauge market is projected to grow at a compound annual growth rate (CAGR) of over 10% between 2023 and 2028, reflecting an increasing demand for sophisticated measurement solutions.

Another trend reshaping the landscape is the emphasis on accuracy and reliability driven by advanced materials and manufacturing techniques. The incorporation of high-quality alloys and composites allows for improved durability and resistance to environmental factors, which is critical in extreme conditions. A survey conducted by the International Society of Automation revealed that over 75% of industry professionals prioritize accuracy and long-term stability when selecting pressure measurement tools. As pressure gauges become more rugged and precise, industries can expect enhanced operational efficiency and reduced downtime, solidifying the essential role of pressure gauges in safe and reliable processes.

Related Posts

-

Ultimate Pressure Gauges Procurement Checklist for Global Buyers

-

Exploring Innovative Alternatives to Traditional Pressure Gauges in Industrial Applications

-

How to Choose the Right Pressure Gauge for Your Industrial Applications

-

How to Choose the Right Pressure Gauges for Your Industrial Needs

-

Exploring Innovative Sprayer Parts at the 138th Canton Fair 2025 Insights and Industry Trends

-

What is a Pressure Regulator and How Does It Work?